Breakthrough in machinery manufacturing

【Tianji Network IT News Channel】Machinery manufacturing industry is the backbone of industrial economic development, especially high-end equipment manufacturing, is the carrier of high-tech industrialization, is the foundation of national defense construction, and is also an important pillar to achieve rapid economic growth. It plays an extremely important role in the quality, stability and industrial restructuring of national economic operation.

Since 2021, for the machinery manufacturing industry, the price of raw materials required for production, such as steel, has fluctuated greatly. How to reasonably control inventory and production costs under the condition that raw material prices are uncontrollable is particularly important. Because in the machinery industry, the price of steel accounts for between 30% and 40% of production costs on average.

Under the dual crisis of the epidemic and the Russian-Ukrainian war, the cost of key raw materials that rely on foreign core technologies and resources is also increasing, such as chips involving core technologies. The price of purchasing a chip rose by several hundred yuan overnight, which brought a lot of cost pressure to enterprises that need to use chips in China, such as agricultural machinery and construction machinery manufacturing enterprises. A new round of price increases is expected in 2022, and the supply-demand imbalance will continue for another year, with prices expected to rise by at least another 10% to 20%.

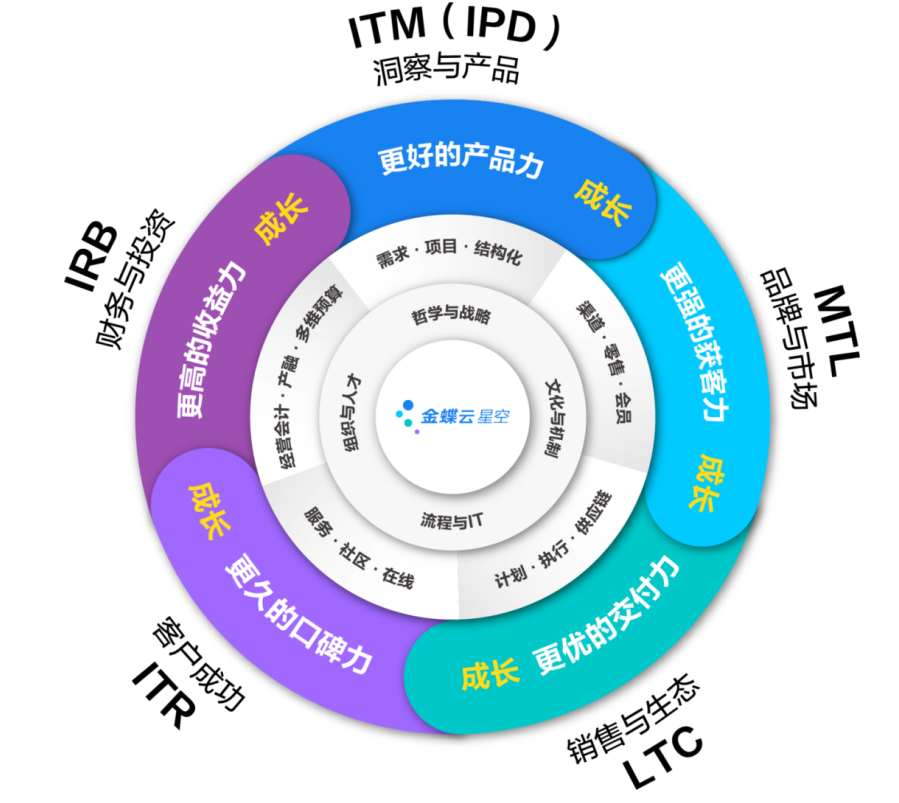

In the data era, data-driven innovation is the essence of enterprise transformation. One of the important criteria for judging the success of an enterprise is whether the operation of the enterprise has formed a "growth flywheel", that is, whether all aspects of the operation of the enterprise are supported by data.

For the machinery manufacturing industry, the "growth flywheel" is mainly composed of five parts: product power (R&D digitalization), customer acquisition power (channel digitalization), delivery power (production digitalization), word-of-mouth power (after-sales service digitalization), and revenue power (financial control digitalization). Due to the uncertainty of supply chain raw materials and costs, the instability of customer needs, how the machinery manufacturing industry can not only meet the personalized needs of customers in the unpredictable environment, achieve an efficient supply chain, but also meet the market demand with shorter delivery time, lower cost and better quality, delivery is particularly important.

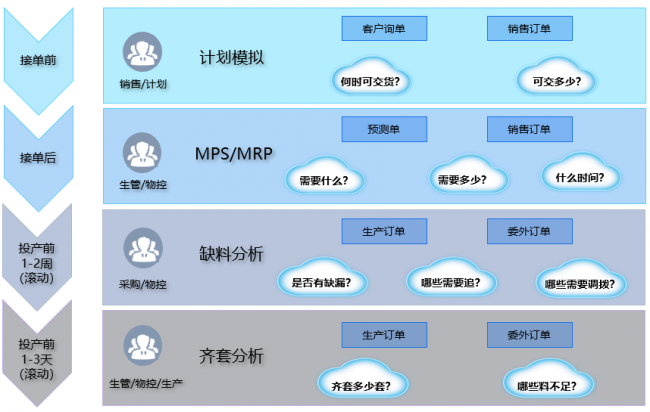

The construction of "delivery power" in the machinery manufacturing industry needs to start from the source of the company's plan. Improve the accuracy and completion rate of the plan, achieve a high degree of matching of the plan and capacity, strengthen the refined control of production management, and carry out all-round digital transformation in the process of on-site management. Only by thoroughly digitizing the production planning and production management of the enterprise can we achieve the "delivery ability" of the company's short delivery time, low cost and high-quality products, and achieve the goal of expanding the market and improving competitiveness.

First, efficient coordination of plan management is the prerequisite for ensuring "delivery power"

1. Plan coordination and realize the balance of man, machine and material

The machinery manufacturing industry needs to formulate a reasonable main production plan according to market forecasts, sales plans, customer orders, comprehensively consider all aspects of resource and capacity constraints, and need to balance with the capacity plans of key resources. According to product attributes, the machinery manufacturing industry has order-oriented, inventory-oriented and assembly-oriented production methods, so it is necessary to consider the shortage of materials and plan the planning strategy of raw materials, self-made parts, purchased parts, and outsourcing materials.

Please first Loginlater ~